- 2月 25, 2021

- News

- 0 Comments

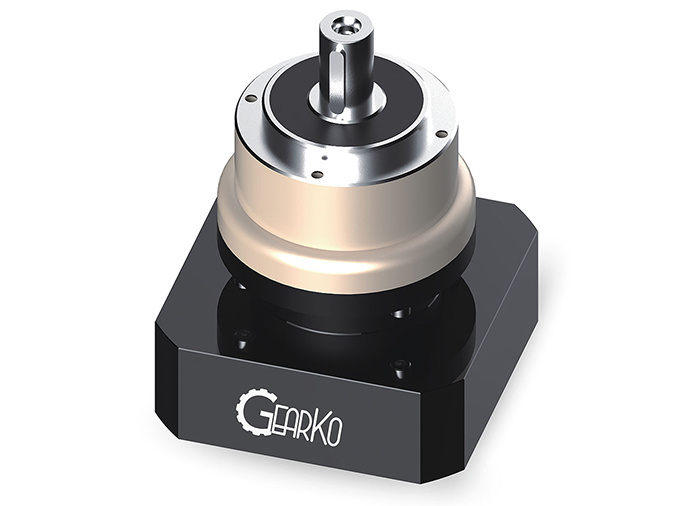

How to choose a good planetary gearbox, be sure to look at the axis of the planetary gearbox. The planetary gearbox is secured by the motor and the coupling joint. Planetary gearbox manufacturers will provide you with performance and performance information for planetary gearbox couplings.

There are many configurations of couplings used on planetary gearboxes, such as: cross shaft, ball cage, ball fork, bump, ball pin, ball nest joint, ball plunger pump, three pins, three claws, three balls, hinges, etc. The main type is the horizontal axis type, followed by the ball cage dragon. The common feature of planetary deceleration couplings is that they have a large amount of angle compensation, not the same structure. The centerlines that are coupled by two shapes have different intersecting angles, typically ≤5 to 45 degrees.

Due to the structural characteristics of the coupling, the centerline of the two axes is different, and the two axes of the coupling rotate continuously within the intersection of the center line, thus reliably transmitting torque and adaptation mode. Large angle compensation, compact structure and efficient transmission system are the main features of couplings. In fact, it is divided into overweight, medium, small, light, medium and small by the size of the transfer torque.

A mechanical component that is connected to two axes (active and edratic) in different tissues so that they rotate to each other to transmit torque. Some couplings also act as buffering, damping and improving the daily power of the idle and light-duty drivetrain shaft systems. The coupling is made up of two parts, which are connected to the drive shaft and the driven shaft, respectively. Most general-purpose power machines are connected to working machinery through couplings.

There are several types of couplings, which can be divided into dynamic couplings according to their relative position and the change of the relative position of the two axes. For areas where the two axes are strictly aligned, there is no relative offset when running. This structure is generally simple and easy to do, and the transient speed ratio of the two axes is the same. The focus is on the falane connection and the casing connection. Shafts, couplings, etc. Active coupling, suitable for the two-axis tilt or relative offset area of work, according to the compensation offset can be divided into rigid and elastic active coupling.